It was the the Fall of 2012. My wife Kay and I were visiting North West Arkansas. Among our stops was Eureka Springs, a small town known for its scenic beauty and where history and nature are crammed into a compact space. Some of the homes and shops seem to barely hang onto the steep rocky hillsides influencing the very architecture to the point that often you will see wedge shaped Victorian-ish structures that are fitted tightly between a very narrow road and a boulder.

The streets are lined with shops offering everything from glass beads to hand made fudge and whose entrances are tucked into alcoves and have old doors that tinkle with copper bells when opened. It’s a place where couples would hold hands and stroll unhurried just soaking in the quaint sights and smells of a life so different perhaps than their own.

That was just what Kay and I were doing when we saw a shingle over an alcove that read “Meteorites” with an arrow pointing to the door. For some time Kay and I had been enjoying a Discovery Network show called “Meteorite Men” and this caused us to walk in the door of the shop for a closer look. Up a long set of narrow stairs was a neat little shop and on the wall behind the counter was a framed poster of the Meteorite Men. Imagine our surprise when out stepped Steve Arnold, one of the guys on the show! After our introduction we look through his amazing shop and talked back and forth, I mentioned that I made knives and was contemplating using a meteorite in the process.

Steve was excited about the idea from the start and offered to send me a particular piece of meteorite to use. I jumped at the opportunity and that was the beginning of this year long project.

Since I had never used meteorite in a damascus billet, I took my time learning and considering the possible pitfalls that would arise. But aside from the actual blending of the metals to make the blade, there is another characteristic of this particular meteorite that I wanted to showcase in this knife. Meteorite material is essentially iron that has been “smelted” in zero gravity and untouched by humans till it arrived on earth. The conditions in which it becomes iron also gives the inside of the piece a pattern which looks like crystals that cross hatch throughout it.

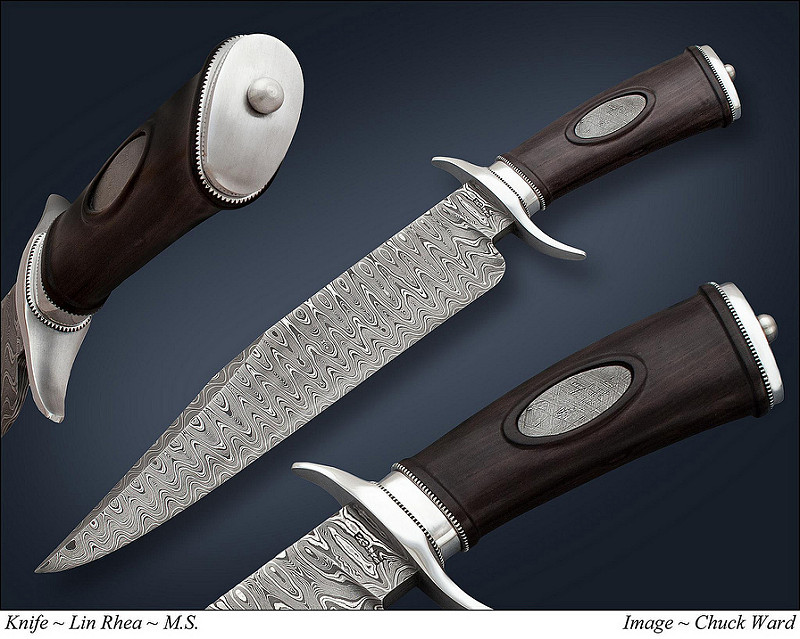

When it is cut and etched, you can easily see it. The crystals are in different sizes according to the actual conditions during it’s formation, sometime very large (an inch or more wide) down to a finely condensed pattern. So, no matter what amount of meteorite’s material I used for the blade’s damascus, thereby destroying the visible pattern , my intentions were to save some material intact to preserve the unique pattern that this individual piece of meteorite had to offer and then set that piece into the knife’s handle.

When it is cut and etched, you can easily see it. The crystals are in different sizes according to the actual conditions during it’s formation, sometime very large (an inch or more wide) down to a finely condensed pattern. So, no matter what amount of meteorite’s material I used for the blade’s damascus, thereby destroying the visible pattern , my intentions were to save some material intact to preserve the unique pattern that this individual piece of meteorite had to offer and then set that piece into the knife’s handle.

The forging of the billet: There were a couple of issues with using meteorite iron in damascus that I had picked up on in my research. One was the tendency for the blade to have soft spots and the other was warping due to the difference in expansion rates of the materials. And since I only had one try, I figured I had better get it right the first time. To accomplish this I had to do about three things at once.

-Number one, I needed to use enough high carbon steel in the mix to end up with a level of carbon to insure a blade that will harden in the quench. I used 1084 and 15N20 for the majority of my billet. I’m familiar with these steels and they provided not only the needed carbon, but a baseline from which to gauge my heat treat. The carbon level supplied in the two higher carbon steels and the complete lack of carbon in the iron will average into a new level. This level, while high enough to achieve hardness, is lower than the two steels used to begin with. This will likely mean that I should temper the blade at a slightly lower draw back temperature than I would for either of the two high carbon steels used without the iron. This would all depend upon the ratio of iron to steel and thus the research ahead of time. Again, if you draw it back on the low side and file test or Rockwell test you can dial in the proper hardness for the type of blade you are making.

-Number Two, I needed to get the iron dispersed evenly throughout the billet. This was done by physically stacking the iron where I wanted it in the billet and keeping it regularly spaced during the subsequent stacking process.

-Number Three, I needed to get the layer count up pretty high (250-300 layers) to allow carbon migration into the iron, essentially turning it into steel.

By doing those three things, my hope was to avoid warping in the quench as well as inconsistencies in hardness in the 10 ½ inch finished blade. For anyone who has layered mild steel or iron into their billets this is no secret. However a meteorite, even when sliced by a saw, has it’s own peculiarities that will have to be considered within it’s own merit. Some meteorites are crumbly, some have other materials that have to be eliminated from the piece before it can be layered into the billet, and other issues that I can only guess about. I imagine this element of uncertainty of outcome along with its perceived otherworldly qualities is what makes its use so very intriguing. Equally intriguing is the actual meteorite from which my slice came. This meteorite is called “The Gibeon Anvil”. Yes, an ANVIL!

I asked Steve about the Gibeon Anvil. This what he said:

“The Gibeon iron meteorite fell in prehistoric times and is one of the largest asteroid impacts known to science. The mass broke up and fell over what now is Namibia, Africa, where thousands of pieces have been found over the last 200 years. Yet even before then pieces were forged into tools by the natives of that area.

It is awe inspiring to realize that before the “civilized world” had reached their “Iron Age” the peoples living on the savannas of Africa were enjoying what had to have been great prosperity as a result of the tools they were able to make with this anvil!”-Steve Arnold

In case you may have missed it, this 100 pound chunk of iron that fell from the sky was used by someone in the distant past as an anvil to forge tools with, possibly even knives! There is clear evidence that one side of the meteorite has been flatten by years of hammering. Now a small part of it lives in a knife in 2013.

Throughout the development of the blade Steve, while living a few hours away from me, was very attentive and patient at the same time. I knew he was anxious to see the results of the blade’s forging. When I showed him some snap shots he was so excited. From then on I knew he had to be in on it all the way from choosing the handle material up to and including photos with the finished knife.

It’s my hope that the readers of this short account and who want to incorporate a slice of meteorite into a knife blade take away this: Do your research before trying it. Acquire iron meteorite with as few occlusions as possible. Disperse the iron as evenly throughout the blade and get the layer count reasonably high. Then after hardening, start tempering at a lower temperature than what you might expect and test to dial in the proper hardness.

Recent Comments